MILLING MACHINE SERVICES

INDUSTRIAL METAL ROLLS

METAL MACHINE WORKS

LINE BORING MACHINE FOR HEAVY EQUIPMENT

EQUIPMENT FABRICATION REPAIR & REBUILDS

As America’s leading metal fabrication experts, Atlanta General Machine Works use a range of metal forming processes to produce a range of products that have versatile applications across a wide variety of sectors.

Regardless of your industry, our products take your levels of productivity and efficiency to new heights.

We’re proud to use machinery that offers a range of advanced features, with our CNC press brakes being the only product of their kind to feature dynamic crowning. Meanwhile, our six axis back gauge system helps minimize setup time whilst forming complex parts with the highest levels of precision and ease.

SERVICES

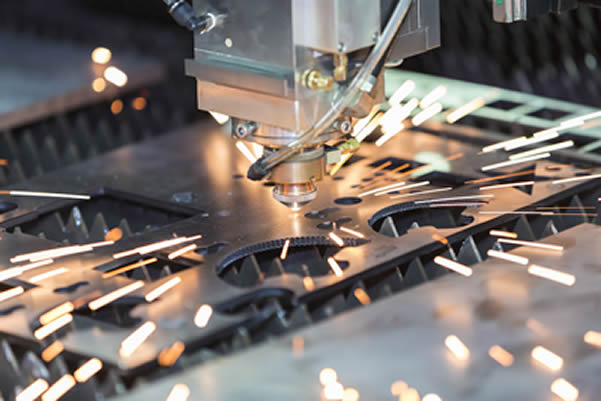

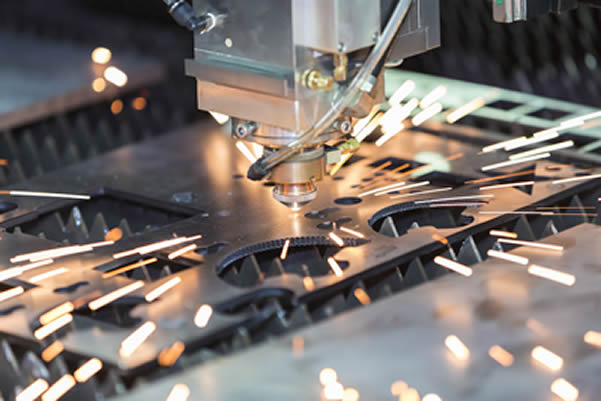

MIlling Machine Services

Our expertise comes from over 20 years of experience in the manufacturing field.

Milling Services allows us to offer our customers unsurpassed machining capabilities.

The equipment we use is highly productive and accurate. Our well trained staff is our assurance of a quality product delivered to our customer.

Industrial Machine and Fabrication Shop

Have the parts for your next project manufactured.

Our experts have the ability to manufacture parts from any material the application requires.

-Has 4-way fork access and a weight capacity of 2,500 Lbs.

Cylindrical Grinding

Atlanta General Machine Works specializes in precision grinding services of polygon components suitable for a wide range of applications.

Our advanced CNC cylindrical grinding machine can deliver outstanding accuracy and precision even on large-scale and complex jobs.

Whether your existing components have failed and need replacing or you need precision polygons for prototyping, our team of experts stands ready to support you.

Industrial Welding

Heavy fabrication welding expert to supply you with the parts that make your equipment work to its full potential, you know that you need a fabrication partner that you can depend on for high quality, on-time production scheduling and delivery and reliability.

From quality components to new innovations to work with your demand schedules, we give you a turnkey solution for all of your OEM welding needs.

Atlanta General Machine Works has the equipment and expertise to be your welding fabrication solution for heavy, complex parts – and the quality practices to get it right each and every time.

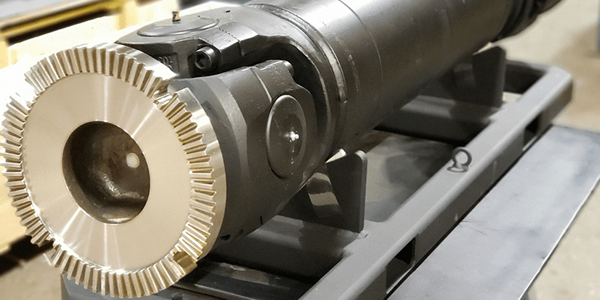

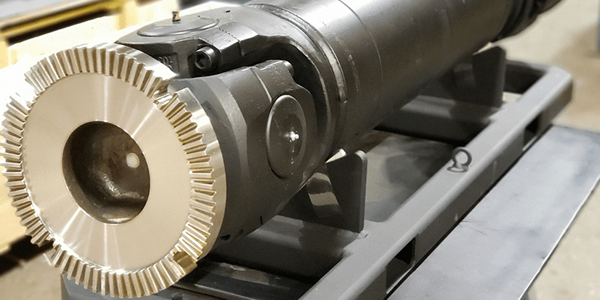

Drive Shaft Fabrication, Repair and Modification

For the heavy-hitting work day, the Professional drive shaft delivers quality components that help equipment operators power through their hardest drive train applications.

Pallet Equipment Maintenance and Modification

Make your equipment more efficient with the properly maintenance

Get your equipment more productive with our proffesional modifications.

Line Boring Machine Services for Heavy Equipment

Engine Blocks, gearboxes, industrial presses, and hydroelectric turbines all require bore centerlines to be collinear. No matter what industry you are in, if your equipment has moving parts, chances are there are bores that simply must be in line for the machine to operate properly.

Our Safety Program consists of many aspects be its training programs, certifications, routine meetings, safe equipment technology, and more. Working safely protects employees, equipment, customers, customer assets, and vendors.

There is no greater priority than Quality Work Done Safely.

Our machinery modification services are open for all types of automation projects, be it adding a totally new machine/method or modifying an existing operation.